Overview

Innovative Kühlsysteme für Brennstoffzellen

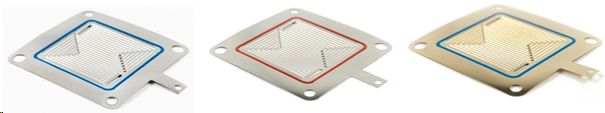

In der Mobilität stellt sich ein Umdenken auf ressourcenschonende und emissionsfreie Antriebe ein. Neben batteriebetriebenen Fahrzeugen sind Brennstoffzellen für die Elektromobiliät im Fokus. Zielführend ist die Reduzierung der Herstellkosten durch großserientechnischen Einsatz metallischer Bipolarplatten, denn dadurch können die Gesamtmasse der Brennstoffzellenstacks sowie anfallenden Produktionskosten gesenkt werden. Die Verringerung des Bauraums führt zu einer Steigerung der Leistungsdichte, wodurch neue Konzepte zur Abführung der Verlustwärme erforderlich werden. Der zuverlässige Funktionsbetrieb des Kühlsystems muss auch bei wechselnden Temperatureinflüssen, Beschleunigungen oder Erschütterungen gewährleistet sein. Entsprechend ist die Dichtung, die das Ausdringen von Flüssigkeiten und Gasen verhindert und für eine elektrische Isolation zwischen den Bipolarplatten sorgt und deren Erforschung sind wesentliche Schwerpunkte im Projekt (Dichtungskonzept und Verarbeitungstechnologien).

Motivation:

- Reduzierung der Herstellkosten von Brennstoffzellenantriebe

- Großserientaugliche Fertigung von metallischen Bipolarplatten

- Steigerung der Leistungsdichte von Brennstoffzellenstacks

Ziele:

- Erforschung eines innovativen Kühlsystems basierend auf der Zweiphasenkühlung

- Übertragbarkeit der Fertigungsprozesse zur Großserienfertigung von Bipolarplatten

- Betrachtungen zur Abdichtung des Brennstoffzellenstacks

- experimenteller Funktionsnachweis unter realitätsnahen Bedingungen

Laufzeit: 01. Juli 2019 bis 31. März 2022 (34 Monate)

Förderung und Projektträger: EFRE, SAB Sächsische Aufbaubank

Partner: WätaS Wärmetauscher Sachsen GmbH, Fischer Werkzeugbau GmbH, CeWOTec Chemnitzer Werkstoff- und Oberflächentechnik GmbH, Technische Universität Chemnitz Professur Mikrofertigungstechnik, Technische Universität Professur Alternative Fahrzeugantriebe

Ansprechpartner: Dr. Phillipp Steinert, philipp.steinert@mb.tu-chemnitz.de

Links zur Projekthomepage: http://wiki.tu-chemnitz.de/HZwoKuehlung/WebHome