Overview

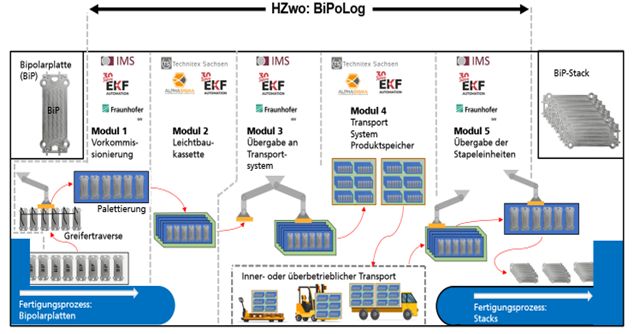

The high-rate capability of the entire production chain is the key to the cost-effective production of fuel cell stacks. The transportation between bipolar plate production and the stacking process poses a particular challenge, as a variety of production solutions exist, from complete production lines within a building to completely separate production sites. The project aims to develop a system that combines removal handling, temporary accommodation, transport and output handling and represents the trouble-free, requirement-oriented link between BiP production and fuel cell production. The quantitative target is 100 pieces of two-part bipolar plates (BIPs) per minute. To achieve this, the extremely sensitive BIPs are gently removed from the production line, grouped into stacking units, fed to a transfer or storage system and fed into the stacking process.

Motivation:

- Ensuring high-rate capability as the key to cost-effective fuel cell production

- Establishment of a value chain for future drive components in the automotive state of Saxony

- Development and establishment of special know-how for handling fuel cell elements

Aims of the Project:

- Development of a flexible logistics concept for different production scenarios

- Gentle removal and clustering of BIPs

- Lightweight transport system for BIPs for different transport tasks including sensor technology

- Demonstrator to prove the development results

Project funding organisation and project executing organisation:

SAB Sächsische Aufbaubank

Link to project homepage