Übersicht

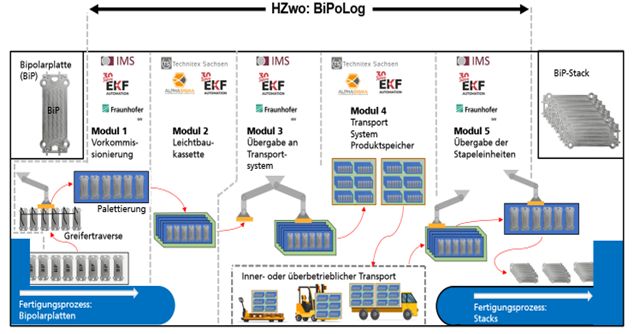

Die Hochratenfähigkeit der gesamten Produktionskette ist der Schlüssel zur kostengünstigen Fertigung von Brennstoffzellen-Stacks. Dabei stellt der Transport zwischen Bipololarplattenfertigung und Stacking-Prozess eine besondere Herausforderung dar, da eine Vielzahl von Produktionslösungen existieren, von kompletten Produktionslinien innerhalb eines Gebäudes bis hin zu örtlich vollständig getrennten Produktionsstandorten. Im Projekt soll ein System entwickelt werden, welches Entnahme-Handling, temporäre Unterbringung, Transport und Ausgabe-Handling zusammenfasst und die störungsfreie, anforderungsgerechte Verkettung zwischen BiP-Herstellung und Brennstoffzellen-Fertigung darstellt. Die quantitative Zielstellung beträgt 100 Stück zweiteiliger Bipolarplatten (BIPs) pro Minute. Dafür werden die überaus sensitiven BIPs schonend aus der Fertigungslinie entnommen, in Stapeleinheiten (SE) zusammengefasst, einem Transfer- oder Speichersystem zugeführt und dem Stackingprozess zugeführt.

Motivation:

- Gewährleistung der Hochratenfähigkeit als Schlüssel für kostengünstige Brennstoffzellenfertigung

- Ansiedlung einer Wertschöpfungskette für zukünftige Antriebskomponenten im Autoland Sachsen

- Aufbau und Etablierung von speziellem Know-How zum Handling von Brennstoffzellenelementen

Ziele:

- Entwicklung eines flexiblen Logistikkonzeptes für unterschiedliche Produktionsszenarien

- Schonende Entnahme und Clusterung der BIP

- Leichtbau-Transportsystem für BIPs für unterschiedliche Transportaufgaben einschließlich Sensorik

- Demonstrator zum Nachweis der Entwicklungsergebnisse

Förderung und Projektträger:

SAB Sächsische Aufbaubank

Link zur Projekthomepage